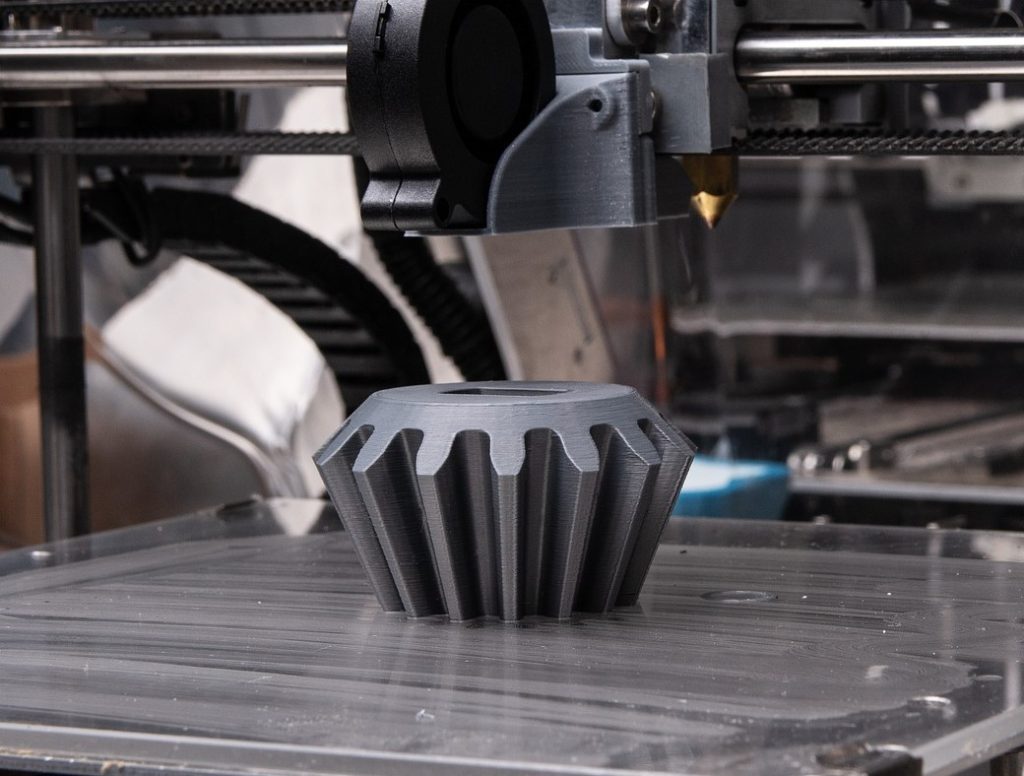

Fused Filament Fabrication / Fused Deposition Modelling

Fused Filament Fabrication (FFF) or Fused Deposition Modelling (FDM) is the most commonly available 3D Printing process. It is an additive manufacturing technology that selectively deposits molten polymer to construct parts layer by layer. The technology is limited by its need for support material to generate overhangs. These limitations must be kept in mind when designing for FDM to achieve the best result. Our FDM service is used for design verification and manufacturing quick prototypes, tooling aids and production parts. Datum offers a comprehensive range of materials and sizes to achieve your bespoke 3D printing needs.

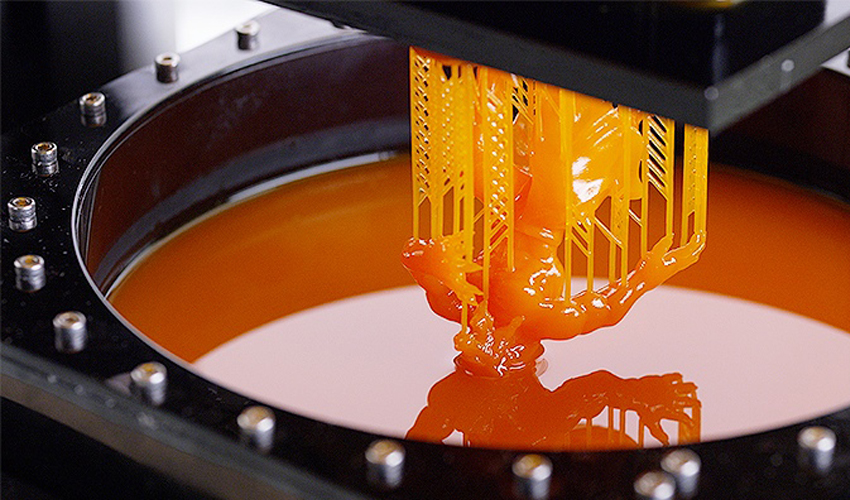

Stereolithography

Stereolithography (SL) is the most widely used 3D Printing technology and it is generally considered to provide the greatest accuracy and best surface finish of any prototyping or 3D printing process. Stereolithography is an industrial 3D printing process used to create concept models, complex or even very intricate parts. It is a popular choice as many parts can be built in just a day! With Datum's secondary finishing services such as painting and finishing we can make your part and the details within it really stand out.

What We Offer

Maximum Part Size: 300 x 300 x 600 mm

Minimum Part Size: 10 x 10 x 10 mm

Lead Times: From 1 Working Day

Tolerance: ± 0.5% (min: ± 0.5 mm)

Layer Height: 100 microns (if applicable)

Minimum Wall Thickness: 1.0 mm